Discovering Cement

"The fact of being able to create fused stones, of whatsoever form, superior to natural stones because capable of standing up under traction, has something of a magic"

It's with Pierluigi Nervi's words, a master of 20th Century architecture, that we wish to start our trip to cement discovery.

Born of stone and fire, cement is a natural product that adapts to human genius in an effort to improve our living standards. Houses, roads, bridges, dams, hospitals, churches originate from architects' creativity and men's building skills. But it is cement that makes all of these works take shape and it is also thanks to cement that even the most daring structures will endure throughout the ages.

- How is cement made ?

-

Cement is obtained from limestone and clay, two naturally occurring raw materials. Extracted from quarries usually located near the cement plants, limestone and clay undergo local primary crushing to have their size reduced and to facilitate transportation to the manufacturing plants

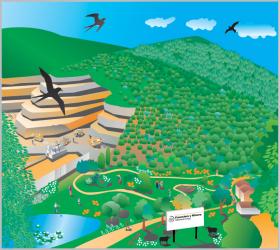

- Restoring quarries

-

Quarrying is combined with studies of landscape rehabilitation and recovery techniques. Rehabilitated areas go on to be used for farming and agriculture,; rebuilding ecosystems through revegetation and reforestation; creation of leisure areas, nature parks and gardens; or the establishment of new industrial, craft or commercial spaces.

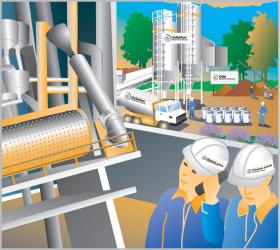

- Grinding and Drying

-

The first step in the processing of raw materials into cement is grinding and drying. The raw materials, adequately proportioned and possibly incorporating additives, are ground into a very fine powder, called raw meal, which is then transported to blending silos and finally sent to storage.

- Burning

-

The raw meal is then fed to the kilns and is heated up to 1450°C in order to obtain clinker, whose components impart hydraulic properties to cement.

The clinker is then removed from the kiln, rapidly cooled and then stored. - Central Control Room

-

The entire cement manufacturing process is continuously monitored and controlled from either small department rooms or a single central control room. All data relating to production as well as quality and environmental controls are displayed 24 hours a day on computer monitors. Skilled technicians are able to promptly identify any possible anomaly or danger and take either corrective or preventive action to regain control of the system.

- Finish Grinding

-

The final step of the cement manufacturing process consists of grinding clinker blended with gypsum and other secondary constituents. This technique results in the production of most types of finalized cement. The cement is then stored in specially-devised silos.

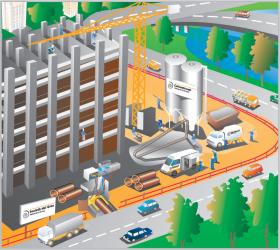

- Final Products

-

Cement is dispatched to customers either loaded in bulk into road tankers or packed into bags, depending on its intended use. The cement is accompanied by transport documents, 25- and 50-kg bags, labels for trucks as well as an attestation of conformity in compliance with regulations and Suez Cement’s policy on the control, maintenance and continuous improvement in product and service quality.

- Distribution Network and Technical Assistance

-

Suez Cement Group manufactures and distributes three main product lines: cement, aggregates and ready-mixed concrete. We aim to optimize production across all of our markets, providing a complete solution for customers’ needs at the lowest possible cost, an approach we refer to as the strategic integration of activities.